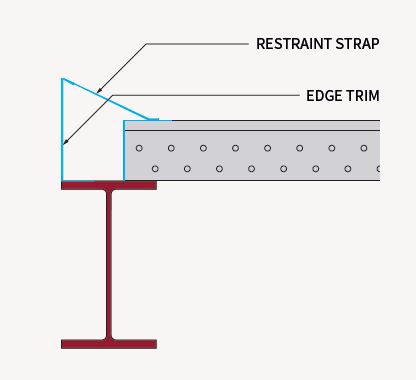

The Edges of Concrete Floor Slabs are usually formed by using Concrete Slab Edge Shuttering, which acts as a permanent formwork to the edges of the slabs and any internal openings within the floor slab. This is made from pressed strips of light gauge galvanised steel. The concrete edge shuttering is manufactured to the the same height as the required slab thickness which guarantees the slab is at the exact height required and also maintains a perfect slab edge. This is achieved not only by the strength of the edge shuttering but also by the galvanised steel strips which fix to the upper part of the edge shutter every 600mm for additional reinforcement to the up stand.

The Edges of Concrete Floor Slabs are usually formed by using Concrete Slab Edge Shuttering, which acts as a permanent formwork to the edges of the slabs and any internal openings within the floor slab. This is made from pressed strips of light gauge galvanised steel. The concrete edge shuttering is manufactured to the the same height as the required slab thickness which guarantees the slab is at the exact height required and also maintains a perfect slab edge. This is achieved not only by the strength of the edge shuttering but also by the galvanised steel strips which fix to the upper part of the edge shutter every 600mm for additional reinforcement to the up stand.

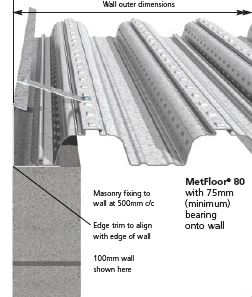

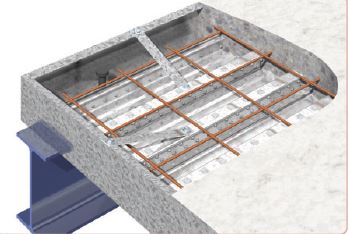

Our Concrete Slab Edge Shuttering is widely used on steel and metal decking projects when pouring concrete in-situ onto the metal decking floors. Once the steel decking has been laid, the edge shuttering is then fixed around the perimeters of the slab and any internal openings within the slab. Concrete can then be poured in-situ onto the metal deck floor to the required height of the slab.

Our Concrete Slab Edge Shuttering is also widely used on pre-cast concrete slab projects. The Edge Shuttering is perfect for creating permanent edge formwork to any channels in the slab which have to be poured in-situ.

We are able to offer every type of edge trim and thickness that you may require. From 0.7mm to 2mm thick and from 100mm height to 600mm height.

Additional reinforcement to the edge of the slab comes in the form of galvanised steel strips which are fastened to the upper part of the edge shuttering and fitted to either the metal decking floor or the pre cast concrete planks.

We also manufacture all types of galvanised steel angles, Closure Plates and Rib End Caps to suit all steel decking profiles such as Metfloor 60, RLSD Ribdeck E60, Comflor 60, Kingspan Multi Deck 60, Metfloor 80, Ribdeck 80, Comflor 80 and Multi deck 80.